The primary function of a pump adapter is to enable fire trucks to draw water from an outdoor fire hydrant and supply it to the indoor fire water distribution system when the fire pump in the room fails or when there's insufficient water available in the building. Drawing from my years of experience in design, I’d like to share some key considerations regarding the placement and configuration of pump adapters.

First, according to current regulations, pump adapters should be installed within each fire zone, based on the pressure capabilities of fire trucks. In the past, buildings over 50 meters were not served by fire engines, and pump adapters weren’t required. However, with advancements in firefighting technology, many cities now have high-capacity fire engines capable of reaching much higher elevations. Therefore, the 50-meter threshold should no longer be used as a strict boundary for installing pump adapters.

When designing a vertical zoning system, it’s sometimes possible to merge pump adapters between zones, rather than installing them separately. Some designs place the pump adapter before a pressure-reducing valve, which can artificially limit the water supply and cause issues with pressure balance, potentially leaving certain floors without adequate pressure during a fire.

In my view, the pump adapter for the low zone should be located after the pressure-reducing valve. For low-zone systems, the lower hydrants can be equipped with pressure-reducing valves, and the low-pressure network can be designed to handle up to 1.6 MPa or 2.5 MPa depending on the building height. Modern fire engines typically have pump pressures ranging from 1.12 to 1.37 MPa, so placing the pump adapter after the valve avoids overpressure issues. A check valve can also be used to prevent high-pressure water from flowing back into the low zone.

Second, in a self-contained fire suppression system, the pump adapter can be directly connected to the wet alarm valve. This allows the fire truck to immediately supply water to the system upon arrival, eliminating the need to activate additional components like the pressure switch or hydraulic alarm bell again.

Third, the distance between the pump adapter and the fire water tank should be between 15 and 40 meters, as per fire code requirements. Similarly, the distance between the pump adapter and the outdoor fire hydrant or fire pond should also be maintained within this range. Fire ponds should store all necessary indoor and outdoor fire-fighting water, and if a reliable water source is available, supplemental water may be subtracted. Outdoor hydrants serve as backup, so maintaining the correct distance is crucial for efficient water retrieval.

Fire trucks also require sufficient space to maneuver, so pump adapters shouldn't be placed too close together. If each pump adapter requires a flow of 10–15 L/s, and the total indoor fire demand is 40 L/s, at least five pump adapters may be needed. Balancing proximity to the fire pond while avoiding interference between vehicles is a complex challenge.

To address this, I recommend installing a dedicated loop pipe outside the building with multiple outdoor hydrants. Each hydrant should be no more than 40 meters from the water intake point. During a fire, the fire truck can take water from the municipal network, then transfer it via the pump adapter to the building. An anti-pollution air break valve should be installed to prevent backflow into the municipal system. If the municipal pipeline is damaged, the hydrants can still function effectively.

Fourth, the number of outdoor fire hydrants should correspond to the number of pump adapters. Each hydrant provides 10–15 L/s, and the pump adapter flow rate is calculated based on the combined demand of the indoor fire hydrant and sprinkler systems. When indoor demand exceeds outdoor capacity, the hydrants must match the number of pump adapters to ensure full coverage during system failures.

It’s also recommended to distinguish between pump adapters for sprinkler and hydrant systems when they are separate, allowing fire trucks to target specific areas and save critical time during emergencies.

Finally, safety valves should be installed in the fire protection system to prevent overpressure. In cases where the fire pump malfunctions or only a small amount of water is being used, sudden activation of nozzles can cause high pressure and potential damage. Installing a safety valve inside the pump adapter helps maintain system integrity and reliability.

Overall, careful planning and adherence to modern fire safety standards are essential for effective fire protection systems.

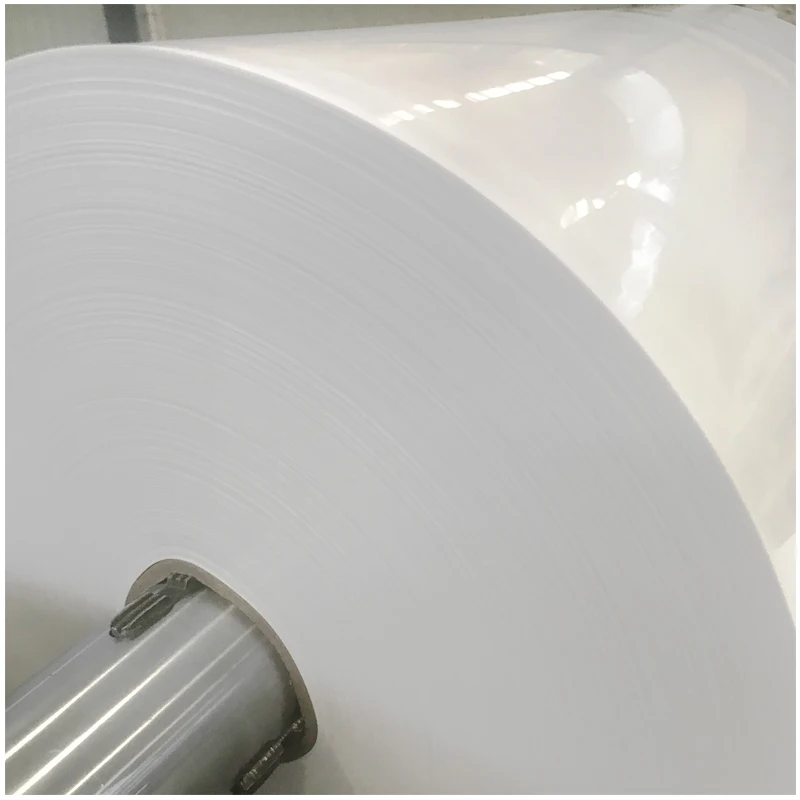

PS Film

Product Description:

Clear High Impact Polystyrene Plastic Sheet (HIPS) for Vacuum Forming

manufacturer thermoforming rigid PS film / white HIPS plastic sheet rolls

High Impact Polystyrene Hips manily to solve the impact brittleness of PS, can be produced different performance and various grades of high impact polystyrene sheet, such as flame retardant grade, high gloss grade, extremely high impact intensity grade and low residual volatile etc.

Our company introduced the newest muli-layer co-extrusion, equipment, could produce , using health grade modified polystyrene, our product conform to government standard, performance PS Sheet according to your requirements.

PS applications:

1. blow molding board, CNC engraving materials, laser engraving materials, sign board, light box, window, logo and mark, etc. HIPS also applies to food packaging, milky tea cup lid, moon cake tray, cookies tray. Electronic tray, cosmetics package and other fields.

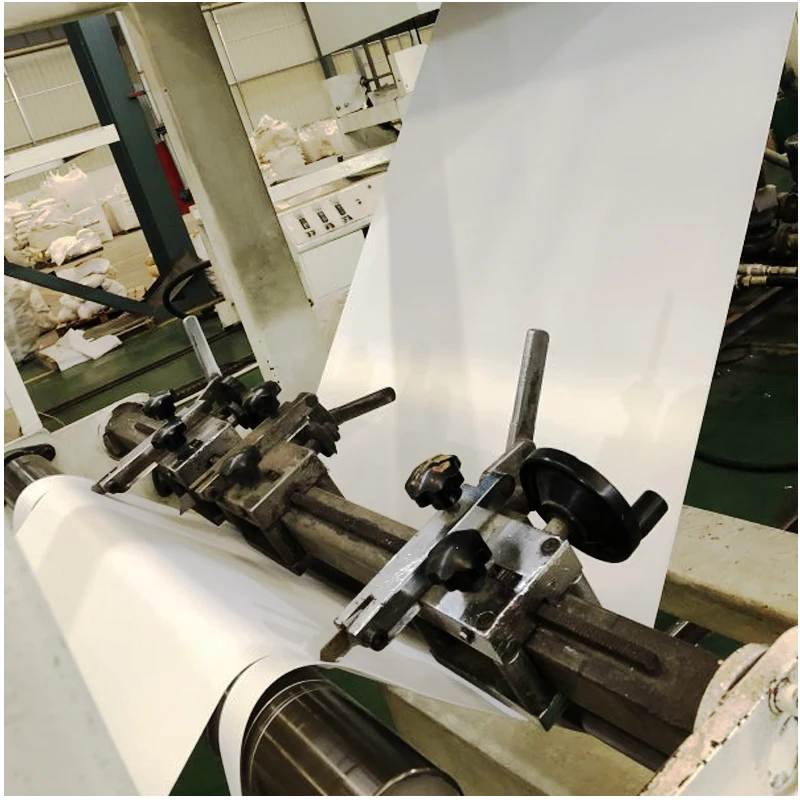

HIPS Plastic Sheet Features

1. easier process

2. good dimensional stability, high impact strength, high rigidity, heat deflection temperature is 96°, material specifi gravity is 1.05.

3. excellent recovery features, is high quality environmental protection material.

4. Thickness: 0.16-1.5mm

5. Max Width: 900mm

6. Non-toxic and chemical resistant

7. SGS certification and food thickness range0.16-1.5mm

8. natural color, teeth yellow color, coffee color, golden yellow color, brilliant orange color, porcelain white color, black color and all sorts of HIPS sheet.

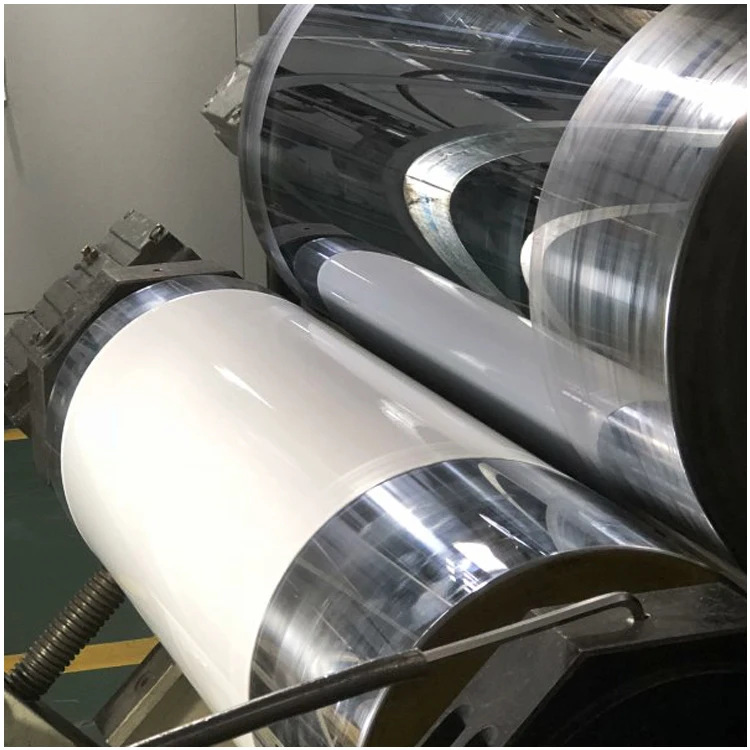

Packing

Packaging & Shipping for Plastic Sheet:

1. Sample packaging by covered by film or Craft paper.

Delivery

2. LCL & FCL packaging by wooden pallet outside and plastic bag inside ,or according to the customers' requirement.

Ps Film,Ps Protective Film,Transparent Ps Plastic Film,Ps Film For Plastic Cup Lids

Shandong Top Leader Plastic Packing CO., LTD , https://www.sdzlplastic.com