Discovering the Versatile World of ABS Resins: Strength, Durability, and Flexibility in Manufacturing

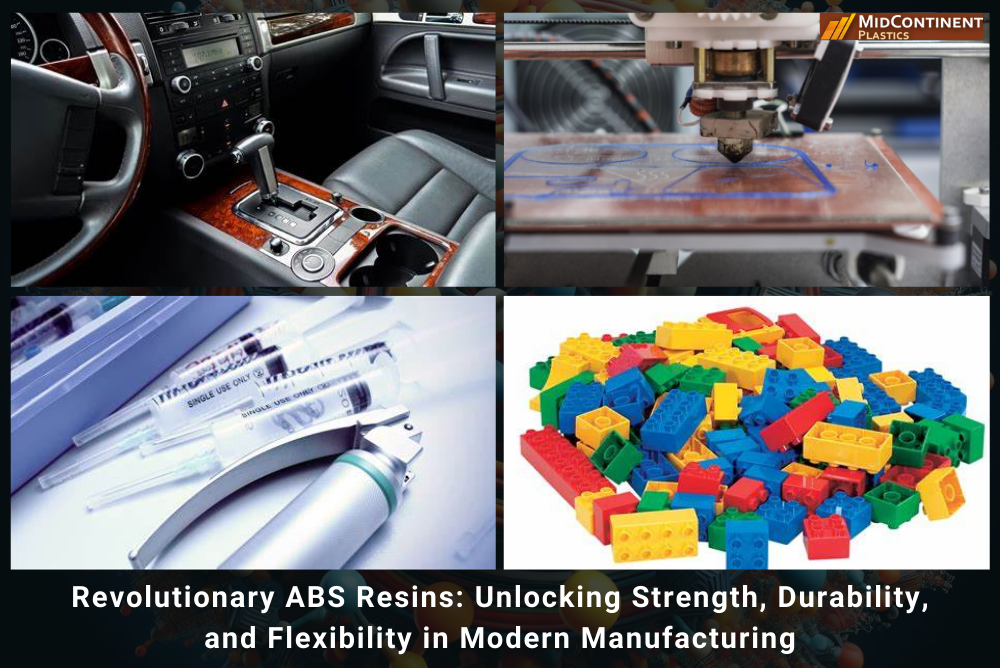

When it comes to manufacturing, engineers and designers are always on the lookout for materials that offer a perfect balance of strength, durability, and flexibility. One such material that has gained widespread popularity is ABS resin—Acrylonitrile Butadiene Styrene. This versatile polymer has become a go-to choice across various industries due to its unique combination of properties. In this post, we’ll explore what makes ABS resins so special, their key characteristics, and where they are commonly used.

What Are ABS Resins?

ABS resins are a type of thermoplastic polymer made by combining three monomers: acrylonitrile, butadiene, and styrene. This blend gives the material a unique set of properties that make it highly suitable for a wide range of applications. As a copolymer, ABS benefits from the strengths of each individual component, resulting in a material that is both strong and flexible. It's widely used in everything from automotive parts to electronic enclosures and even medical devices.

Key Properties of ABS Resins

Here are some of the most notable properties that make ABS resins stand out:

- Excellent Impact Resistance: The butadiene component in ABS provides it with high impact strength, making it ideal for parts that may be subject to sudden forces or collisions.

- Good Flexibility and Ductility: Unlike some rigid plastics, ABS can be stretched or bent without breaking, offering a good level of flexibility.

- High Tensile Strength: ABS is known for its ability to withstand tension and stress, making it suitable for structural components and load-bearing applications.

- Dimensional Stability: Even under varying temperatures and environmental conditions, ABS maintains its shape and size over time, ensuring long-term performance.

- Easy to Process and Color: ABS can be easily molded, painted, and colored, giving manufacturers and designers a lot of creative freedom when it comes to aesthetics.

Common Applications of ABS Resins

Due to its versatility and performance, ABS is used in a wide array of industries. Here are some of the most common areas where you'll find this material:

- Automotive Industry: ABS is used for interior and exterior components like dashboards, door panels, bumpers, and grilles. Its toughness and resistance to impact make it a top choice for vehicle parts.

- Electronics and Appliances: From computer cases to TV housings and appliance parts, ABS is favored for its insulation properties and resistance to heat and chemicals.

- Consumer Goods: Toys, kitchenware, luggage, and cosmetic containers often use ABS because it offers a great balance of strength, durability, and visual appeal.

- Construction and Architecture: ABS is used in pipes, fittings, and decorative elements due to its resistance to weathering and chemicals.

- Healthcare and Medical Devices: Because of its biocompatibility and ease of sterilization, ABS is used in medical equipment, prosthetics, and diagnostic tools.

With its impressive combination of strength, flexibility, and processability, ABS resins have become an essential material in modern manufacturing. Whether you're looking for durable automotive parts, sleek electronics, or reliable medical devices, ABS is a material that continues to prove its value. If you're in need of high-quality ABS resins, consider partnering with Mid Continent Plastics. They offer a wide range of volumes and expert support to help you meet your specific needs. Reach out to them today to learn more about how ABS can benefit your next project.

windshield wiper blades, car wiper blade, heavy duty truck wiper blades, hybrid wiper blades, commercial wiper blades

Taishan Yuanjin Auto Parts CO., LTD , http://www.tsyuanjin.com