Discovering the Versatile World of ABS Resins: Strength, Durability, and Flexibility in Manufacturing

When it comes to manufacturing, engineers and designers are always on the lookout for materials that offer a perfect balance of strength, durability, and flexibility. One such material that has gained widespread popularity is ABS resin—short for Acrylonitrile Butadiene Styrene. This versatile thermoplastic has become a go-to choice across multiple industries due to its exceptional properties and wide range of applications. In this post, we’ll take a closer look at what makes ABS resins so special and why they’re used in so many different fields.

About ABS Resins

ABS resins are a type of thermoplastic polymer made by combining three key monomers: acrylonitrile, butadiene, and styrene. This unique blend gives ABS its remarkable characteristics, making it one of the most widely used plastics in the world. As a copolymer, ABS benefits from the combined strengths of each component, resulting in a material that’s both tough and easy to work with. It's commonly used in everything from consumer products to industrial parts, especially in the automotive and electronics sectors.

Key Properties of ABS Resins

Understanding the properties of ABS can help you make better decisions when selecting materials for your projects. Here are some of the standout features:

- Excellent Ductility: ABS is known for its ability to bend or stretch without breaking, which makes it ideal for parts that need some flexibility.

- High Impact Resistance: The butadiene content gives ABS great toughness, allowing it to withstand sudden impacts and stress without cracking or deforming.

- Dimensional Stability: Even under temperature changes or exposure to different environments, ABS maintains its shape and size over time.

- Good Tensile Strength: ABS can handle tension and weight effectively, making it suitable for structural components and load-bearing parts.

- Customizable Appearance: With a variety of surface finishes and color options, ABS is a favorite among designers looking for both function and style.

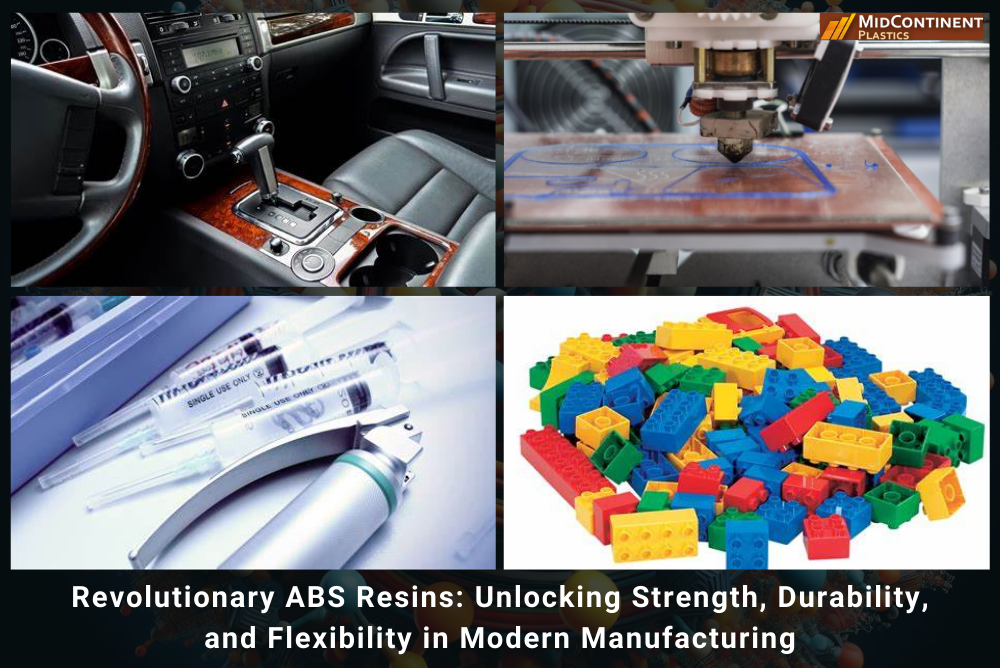

Common Applications of ABS Resins

Due to its versatility, ABS is used in a wide range of industries. Here are some of the most common areas where you'll find this material in action:

- Automotive Industry: From dashboards and door panels to bumpers and grilles, ABS is used extensively in both interior and exterior car parts thanks to its impact resistance and durability.

- Electronics & Appliances: ABS is a popular choice for enclosures, housing units, and internal components due to its insulating properties and resistance to heat and chemicals.

- Consumer Goods: Toys, kitchenware, luggage, and cosmetic containers often use ABS because it offers a great mix of strength, aesthetics, and cost-effectiveness.

- Construction & Architecture: Pipes, fittings, and decorative elements made from ABS are valued for their chemical resistance and long-lasting performance.

- Medical Devices: Its biocompatibility and ease of sterilization make ABS a preferred material in the healthcare sector for devices like diagnostic equipment and prosthetics.

With its impressive combination of strength, flexibility, and adaptability, ABS resins have become a cornerstone in modern manufacturing. Whether you're working on automotive parts, electronic devices, or medical tools, there's a strong chance that ABS is already playing a role in your project. As technology continues to evolve, the demand for high-performance materials like ABS is only expected to grow. If you're looking for reliable suppliers of ABS resins, consider reaching out to Mid Continent Plastics. They offer a wide range of volumes and expert support to meet your specific needs. Don’t wait—contact them today to learn more about how ABS can benefit your next project.

Mini Blade Fuse,Blade Type Fuse,Knife Blade Fuse,Fuse Blade

Taishan Yuanjin Auto Parts CO., LTD , http://www.tsyuanjin.com