Understanding Stockpile Measurement

Stockpile measurement refers to the process of determining the quantity, volume, or weight of bulk materials stored in stockpiles. Businesses handling large quantities of commodities inevitably accumulate stockpiles, typically housed in specialized storage facilities designed for storing bulk materials. These stockpiles are often formed by dumping materials from trucks, moving them with bulldozers, and managing them manually. But how do managers and workers accurately gauge the exact size of these stockpiles?

In the past, workers relied heavily on manual methods or GPS services, which provided estimates within a certain range. However, advancements in stockpile measurement techniques now enable businesses of all kinds to achieve hyper-accurate measurements, enhancing productivity and reducing operational costs.

Sulfur stockpile

## Why Stockpile Measurement Matters

Accurate stockpile volume measurements can provide significant advantages to companies across various industries. Whether you're dealing with coal, ores, fertilizers, or industrial dust, precise stockpile measurements can help you reduce costs and improve operational efficiency.

### Increased Profitability and Efficiency

If workers are merely estimating stockpile sizes, there's a high chance of materials being wasted. Traditional measurement methods have limitations, and for every pound of material not accurately measured, profits could be lost.

With advanced stockpile measurement solutions, businesses can minimize excess inventory and the associated costs. These measurements also help companies decide when to reorder or resume mining activities, allowing them to better plan for machine downtime and optimize workforce allocation. This leads to savings in maintenance, repair, and labor costs.

Accurate stockpile measurements also enhance strategic decision-making, resulting in increased productivity and higher profits. Investing in upgraded measurement tools offers a solid return on investment due to these tangible benefits.

### Actionable Data for Strategic Decisions

Properly gathered stockpile data, thanks to modern technology, can be leveraged in numerous ways. We've seen how stockpile calculations can boost internal efficiency, but they also assist businesses in securing loans and complying with tax regulations.

The more precise your stockpile measurements, the easier it becomes to share this data with external entities like financial institutions or regulatory bodies. Companies can use this data for financial reporting, excise duties, and loan applications. Essentially, the more accurate your stockpile data, the more effectively you can utilize it to your advantage.

### Regulatory Compliance

Stockpile measurements also play a crucial role in helping businesses adhere to regulatory standards. For instance, the EU Emissions Trading System mandates businesses to conduct mass balances to calculate CO2 emissions, a task greatly simplified by accurate stockpile management.

Transparency is key here. Regulators and compliance boards prefer verifiable data, and having stockpile measurements recorded to the nearest inch provides assurance that the data hasn't been tampered with or estimated. This mutual trust expedites processes for both the business and the regulatory body.

### Enhanced Worker Safety

Stockpile measurement improves workplace safety by ensuring workers only retrieve materials when necessary. Reducing waste minimizes time spent in hazardous environments, thereby lowering the risk of accidents.

Moreover, cutting-edge stockpile measurement tools like drones eliminate the need for workers to manually measure potentially dangerous stockpiles. This introduces an extra layer of protection between employees and hazardous materials.

Take, for example, a 3D fly-through of salt stockpiles at a salt mine, created using LiDAR data collected by the Elios 3 drone. Such tools not only improve efficiency but also safeguard workers' well-being.

Â

Large stockpiles of dust, stone, or fertilizer can be perilous for workers to traverse manually due to hidden air pockets or unstable surfaces. However, using drones or other robotic tools, companies can eliminate nearly all risks involved.

Finally, effective stockpile management reduces downtime and maintenance costs, making workers less likely to face dangerous situations during repairs when accurate stockpile measurements are in place.

## Which Industries Rely on Stockpile Measurement?

Stockpile measurement is essential in several industries:

### Aggregates

An aggregate is a construction material composed of natural raw materials like sand, gravel, and crushed stone. When combined with a binding agent such as water, asphalt, or cement, aggregates form concrete, which is widely used in infrastructure like roads, bridges, and parking lots.

Managing aggregates presents unique challenges due to their diverse components, which vary in size and texture. Maintaining separate stockpiles for different aggregate mixes is crucial for meeting project-specific requirements.

Stockpile measurement helps ensure that different aggregate mixes remain distinct and prevents cross-contamination. It also aids in protecting inventory from environmental factors like water damage or erosion.

### Construction

Construction suppliers dealing in materials such as sand, wood chips, or asphalt also rely on daily stockpile calculations. These measurements guide inventory management and worker assignments.

In construction, stockpile data is critical for planning hauling routes to and from job sites. Proper stockpile measurements enhance worker safety and satisfaction by providing crane and dozer operators with clear directions and material availability details.

### Mining

Mining operations extensively utilize stockpile measurement solutions to quantify inventories of materials like iron ore and other minerals with remarkable precision.

Modern stockpile measurement tools, such as drones, improve safety by eliminating the need for workers to manually measure hazardous stockpiles filled with sharp or jagged rocks.

Quarry mine stockpiles

Mining sites often span vast areas, sometimes covering thousands of acres with numerous stockpiles. Proper stockpile calculations significantly enhance both worker efficiency and safety.

### Recycling

Accurate stockpile data is vital in industrial recycling and waste management. In a case study by Flyability, a company specializing in recycling industrial dust managed to increase the accuracy of its inventory estimates by over 200% using advanced stockpile measurement and drone technology.

With precise inventory data, the company could predict recycling timelines more accurately and ensure stockpiles remained within capacity limits. This also facilitated compliance with legal storage regulations for various materials.

### Shipping and Ports

Ports and shipping centers are hubs for commodity material stockpiles. Whether dealing with aggregates, ores, chemicals, or agricultural products, stockpiles at these locations require constant oversight.

Stockpile measurement serves similar purposes in shipping and ports as it does in other industries—facilitating route planning, saving costs, and reducing workplace hazards. Given their connection to global supply chains, even minor data discrepancies can lead to losses in fuel, time, or money.

## Techniques for Stockpile Measurement

Stockpile measurement can be performed using several methods, each with varying levels of accuracy and application. Let’s explore some common approaches and their suitability for different scenarios.

Each of these methods follows two general steps:

1. **Data Collection:** Information about the stockpile is gathered using sensors or collectors such as LiDAR scanners, cameras, or smartphones. These devices collect data but don’t perform the complex mathematical calculations required to determine stockpile volume.

2. **Data Calculation:** Computers and sophisticated algorithms analyze the collected data to compute the stockpile’s size, shape, and volume. Processing speed depends on the stockpile’s size, the number of data points, and the desired accuracy. Many companies offer same-day data processing.

Now let’s delve into the specific methods used for stockpile volume calculations.

### Manual Methods

Traditional manual measurement techniques are the least accurate and are now largely obsolete due to cheaper, more precise alternatives. However, if manual methods are unavoidable, there are a few options to consider.

These include using a walking wheel, measuring by truckload or bucketload, or even "eyeing" the measurement. As expected, these methods introduce inconsistencies and inaccuracies.

Such approaches yield estimates rather than precise data. While useful in earlier times, modern stockpile measurement techniques have rendered these traditional methods nearly obsolete.

### Smartphones

If budget constraints are a concern yet accurate data is still desired, your smartphone might be the answer.

Smartphones function well as data collection tools for stockpile measurement. Paired with appropriate data processing software, they can generate accurate and actionable data within 24 hours.

Numerous smartphone apps exist for this purpose, and most operate similarly. Users simply frame the stockpile in their smartphone camera, walk around its perimeter, and record a video. After reviewing the footage, the user uploads it to the cloud for analysis and receives a detailed report.

These measurements are often surprisingly accurate, within a couple of percentage points of higher-priced options. They’re ideal for businesses that can tolerate a slight margin of error or seek an economical solution for stockpile management.

### Photogrammetry

Photogrammetry is a mapping and surveying technique that combines hundreds or thousands of photos to create a detailed 3D model of a subject or location.

Photogrammetry plays a significant role in stockpile measurement and management. While stockpile volume calculations derived from photogrammetry sensors are highly accurate, there are considerations before committing to this method.

First, photogrammetry can be costly. Both the sensors and the drones or vehicles needed to mount them are expensive. Additionally, operating photogrammetry technology often requires a surveyor, ideally hired in-house for frequent inventory updates.

Despite the initial expense, the data collected via photogrammetry sensors is far more comprehensive and accurate than smartphone-generated data. Although processing takes longer, the assurance of precise measurements makes photogrammetry a worthwhile investment.

### LiDAR

LiDAR works similarly to sonar or radar but uses light emitted by lasers instead of sound or radio waves to determine an object’s position.

LiDAR systems are extremely precise and can generate 3D maps akin to photogrammetry sensors. In low-light conditions, LiDAR often surpasses photogrammetry in accuracy.

Like photogrammetry, LiDAR can measure stockpile volumes. However, the same considerations apply when choosing LiDAR over photogrammetry, such as cost and specialized expertise. LiDAR scanners can be handheld or mounted on robotics like drones.

Although LiDAR scanners and supporting equipment are costly, they are suitable for specific situations requiring a higher budget.

Learn more about LiDAR and its applications across various industries.

## Drones for Stockpile Measurement

Regardless of whether you use a camera, photogrammetry sensor, or LiDAR scanner, drones or UAVs are among the best tools for collecting stockpile measurement data. All these tools and sensors can be mounted on drones.

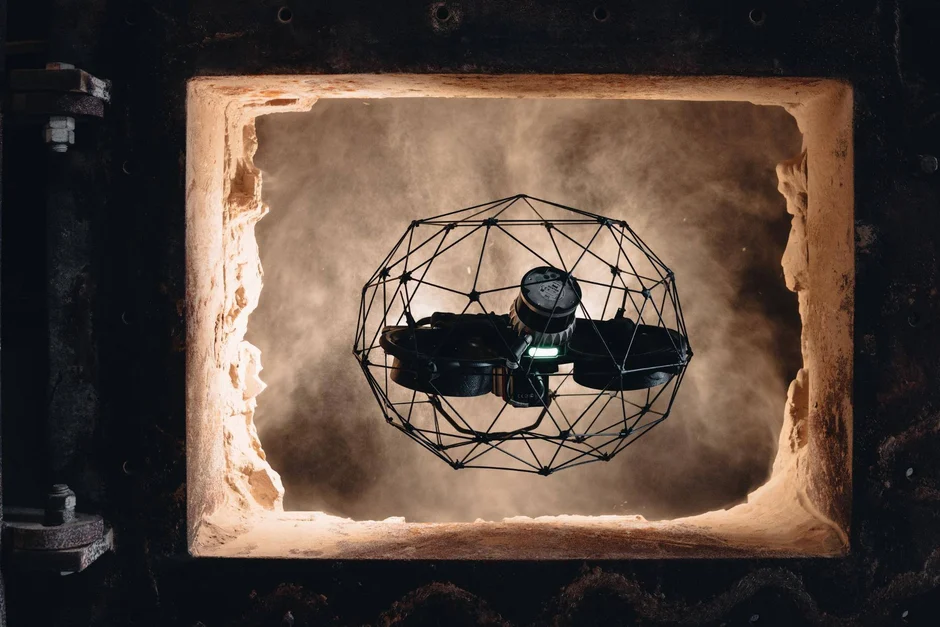

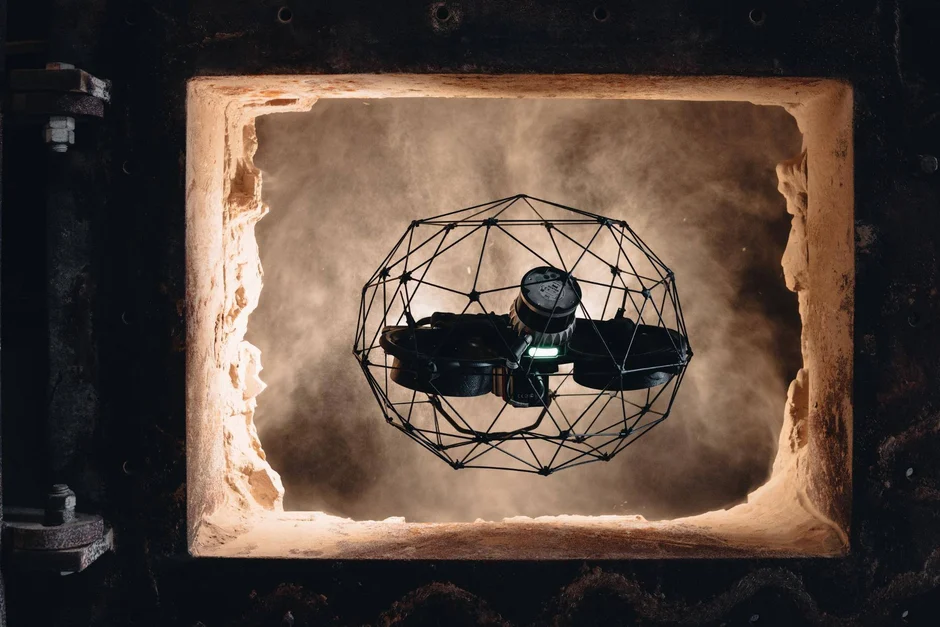

Different situations call for different drones with varying payloads and sensors. For indoor stockpile measurement, a drone like the Elios 3, designed for flying indoors in dark and dusty environments, might be ideal.

The Elios 3 entering an industrial asset for an inspection

In fact, the Elios 3 has already been employed for complex stockpile measurements across industries such as mining, cement, and construction. For instance, the Elios 3 was used to measure stockpiles in a clinker silo, a notoriously dark, dusty, and dangerous environment. In another project, the Elios 3 and its LiDAR payload were used to conduct monthly stockpile checks at a cement plant, surveying 30 stockpiles and bunkers in under two hours.

For outdoor stockpile measurement, drones with long battery life or capable of multiple flights are preferable. Drones working outdoors at sites with multiple stockpiles may need to carry multiple payloads to maximize efficiency.

### Benefits of Using Drones for Stockpile Measurement

Here are just a few ways drones can enhance stockpile measurement solutions:

- **Speed:** Drones can cover extensive areas rapidly—sometimes conducting multiple flights in a single day. At mines or construction sites, a drone can survey acres of land much faster than a human could cover a few hundred feet.

- **Accuracy:** Equipped with photogrammetry or LiDAR payloads, drones like the Elios 3 can measure stockpiles with centimeter-level precision. Whether indoors or outdoors, regardless of the material type or stockpile size, drones collect data more accurately than any manual survey method.

- **Cost:** While the upfront cost of drones is higher than some alternatives, such as smartphones, the return on investment is substantial. Drones can drastically reduce survey and measurement time, cutting days or even weeks off traditional methods. Additionally, their greater accuracy minimizes costs associated with excess inventory.

- **Safety:** Another major advantage of using drones for stockpile measurement is improved worker safety. By reducing the need for workers to tread on stockpiles, drone-based management solutions can save money, time, and lives.

### Upgrading Stockpile Measurement with Drones

Technologies like LiDAR-equipped drones, such as the Elios 3, now make it possible to work faster and more efficiently than ever before. Digital copies of stockpiles created through laser scans or photogrammetry enable clearer reporting, easier communication, and accurate tracking. This visual resource helps prevent errors and monitor changes, resolving potential conflicts or confusion over stockpile depletion or overloading.

The Elios 3 is a game-changer for streamlining complex stockpile measurements, enabling safer, faster, and more accurate data collection—a standard part of industrial operations. With benefits including enhanced safety and reduced downtime, drone-based stockpile measurement represents a significant leap forward across industries, set to become a routine practice in the near future.

Folding Packing With Sealing

A simple version of the automated clothing folding packaging sealing labeling equipment.The machine is versatile, suitable for different kinds of clothing, and cost-effective. A versatile automatic garment folding and packing machine, suitable for thick and thin clothes as well as pants,machine can be equipped with different functions to meet different packing requirements of different customers.

Folding Shirts For Packing, Clothes Folding Machine For Sale, Hospital Clothes Folding Machine, Sugical Gown Folding Machine

SHENZHEN LINGCHUANG ZHUOYUE TECHNOLOGY CO., LTD , https://www.lcautosz.com