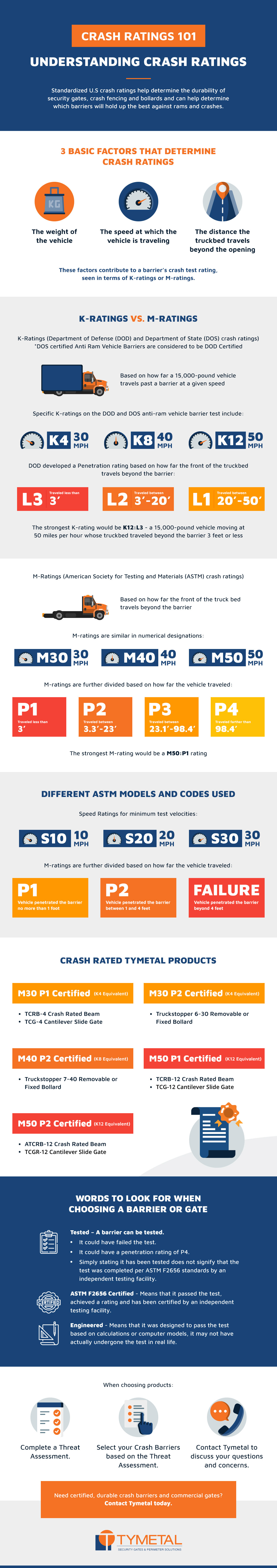

Security barriers and gates play a crucial role in protecting entrances from unauthorized access and minimizing damage during accidental collisions. In today's world, where security is of utmost importance, standardized crash ratings help determine the effectiveness of these protective measures. These U.S.-based ratings are unbiased and provide valuable insights into the durability of security gates and bollards. Understanding crash ratings can help you choose the right barrier for your needs. Whether you're looking for a secure gate or a strong bollard system, knowing how to interpret these ratings is essential. This guide will walk you through the key factors that influence crash ratings, as well as the differences between K-ratings and M-ratings. Three main elements determine a barrier’s crash rating: Some systems only grant certification if the vehicle travels less than a certain distance past the barrier. These three factors together define the classification of a barrier’s crash rating. You may come across terms like K-ratings and M-ratings, so it's important to understand what each means. K-ratings, developed by the Department of Defense (DOD), have been used since 1985. They are based on how far a 15,000-pound vehicle travels past a barrier at a specific speed. For a barrier to be certified under K-ratings, the vehicle must travel no more than 50 feet beyond the barrier. Higher K-ratings correspond to higher test speeds, with the same vehicle type and weight. Examples of K-ratings include: K-ratings are further divided into L1, L2, and L3, depending on how far the vehicle traveled beyond the barrier: The strongest K-rated barrier would be K12:L3, meaning a 15,000-pound vehicle traveling at 50 mph penetrated the barrier less than 3 feet. M-ratings have largely replaced K-ratings and are based on ASTM standards. Unlike K-ratings, which measure how far the front of the vehicle travels beyond the barrier, M-ratings focus on the payload's distance. Both types use similar criteria—vehicle weight, speed, and distance—but M-ratings offer more precise measurements. For example: M-ratings are classified into P1, P2, P3, and P4, based on how far the vehicle's payload travels beyond the barrier: An M50:P1 rating is equivalent to a K12:L3 rating. M-ratings allow for more accurate assessments due to their broader range of distances. It's important to understand the difference between "tested," "certified," and "engineered" when evaluating security products: When choosing a barrier, always look for "certified" ratings. If you see "tested" or "engineered," ask whether the product actually met the required standards or underwent physical testing. ASTM uses models and codes to classify anti-ram tests based on speed, weight, and penetration distance. Here are some common classifications: Penetration ratings for low-speed tests include: For high-speed tests, the standards are slightly different: At TYMETAL, all our security gates and crash barriers are certified to meet prestigious ASTM standards. We ensure that every product is tested and rated to provide the highest level of protection. Explore our durable crash barriers and commercial gates today and experience the difference of certified security. Reviewed By Chris Herold on 4/29/2021 MIG Stainless Steel Welding Wire Mig Stainless Steel Welding Wire,Stainless Wire Welding,Welding Stainless Steel Wire,Stainless Welding Wire Jiangsu Manrui New Materials Co., Ltd , https://www.manruiwire.comA Guide to Understanding Crash Ratings

The 3 Factors That Determine Crash Ratings

K-Ratings: The Older Standard

M-Ratings: The Modern Standard

Tested vs. Certified vs. Engineered

ASTM Models and Codes

Choose Certified Security Gates and Perimeters From TYMETAL