This is a specific kind of tube and shell heat exchanger commonly employed in industries like chemical processing and petrochemicals. Its primary component, the tube bundle, provides excellent thermal expansion capabilities. This means it can accommodate significant fluctuations in temperature without exerting undue pressure on the tubes. This feature makes it particularly suitable for applications involving substantial temperature differences between the two fluids being exchanged.

Table of Contents

- Specification of U Tube Heat Exchanger

- Function of U Type Heat Exchanger

- Features of U Tube Bundle Heat Exchanger

- Design of U Tube Heat Exchanger

- Diagram of U Tube Type Heat Exchanger

- Comparison: U Tube vs Straight Tube Heat Exchanger

- Comparison: Floating Head vs U Tube Heat Exchanger

- Applications of U Tube Condenser

- Benefits of U Tube Shell and Tube Heat Exchanger

- Advantages of U Tube Heat Exchanger

- Disadvantages of U-Tube Heat Exchanger

- Calculation of U Tube Heat Exchanger

- Crossover Temperature of U Tube Shell and Tube

Specification of U Tube Heat Exchanger

| U Tube Heat Exchanger Size |

- 0.010 to 1.500 inch OD

- 0.254 to 38.1 mm OD

|

| Manufacturing Type |

- Seamless

- Welded

- ERW

- Fabricated

|

| Major Components |

- Front Header

- Rear Header

- Tube Bundle

- Shell

|

| Dimensions Standard |

- ASME B16.9

- MSS-SP-43

- ASME B16.28

|

| Manufacturing Method |

- Hot Finished

- Cold Finished

|

| Material |

- Stainless Steel

- Duplex & Super Duplex Steel

- Carbon Steel

- Alloy Steel

- Nickel Alloy

|

| Certificates |

- MTC EN 10204 3.1/3.2

- 100% Radiography Test Report

- Raw Materials Certificate

- Third Party Inspection Report

- NACE MR0175

- NACE TM-0284

- NACE MR0103

- ISO 15156

|

| Origin |

- Japanese

- Korean

- Indian

- Russian

- Ukraine

- USA

- European

|

| Application |

- High-temperature

- Low-temperature

- Very high pressure

|

| Surface Treatments |

- Precleaned

- Cleaned

- Passivated

- Pickled

|

| Short Radius Elbow Standard |

|

| Finish |

- 180 grit polished

- Matt finish

- 320 grit

- Mirror

- Solution annealed

- Annealed & Pickled

- No.4

- 2B

- Cold Drawn

- BA polishing

- 400 grit

- Bright Annealed

- 600 grit

|

| Value Added Services |

- Cutting

- Polishing

- Threading

- Beveling

|

Learn about the features and functions of U tube condenser

Function of U Type Heat Exchanger

A U-tube heat exchanger facilitates heat exchange between two fluids by allowing one fluid to flow inside the tubes while the other flows around the outside. This design performs exceptionally well in scenarios involving high temperatures and pressures.

Features of U Tube Bundle Heat Exchanger

- Efficient heat transfer

- Fixed at both ends ensuring unidirectional flow of fluids

- Easy maintenance

- Easy cleaning

- Capable of handling high pressure and temperature

U tube bundle heat exchanger offers efficient heat transfer with a compact design

Designed to maximize heat transfer efficiency, this exchanger minimizes energy consumption and operational costs. It exhibits strong pressure resistance and superior heat transfer performance, resulting in improved overall heat transfer capability.

Design of U Tube Heat Exchanger

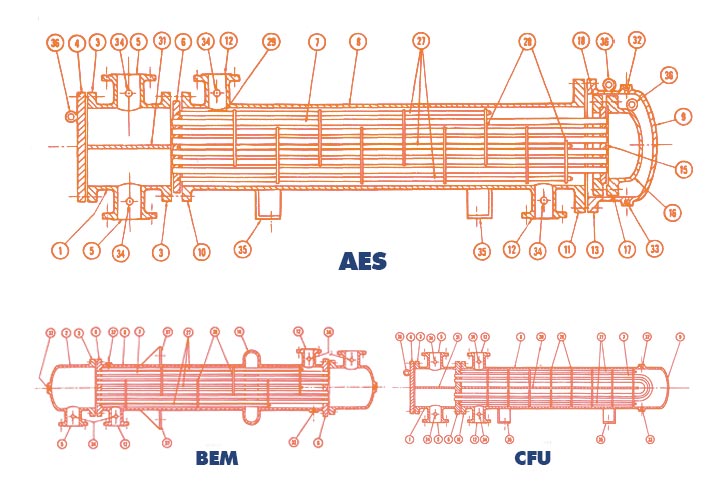

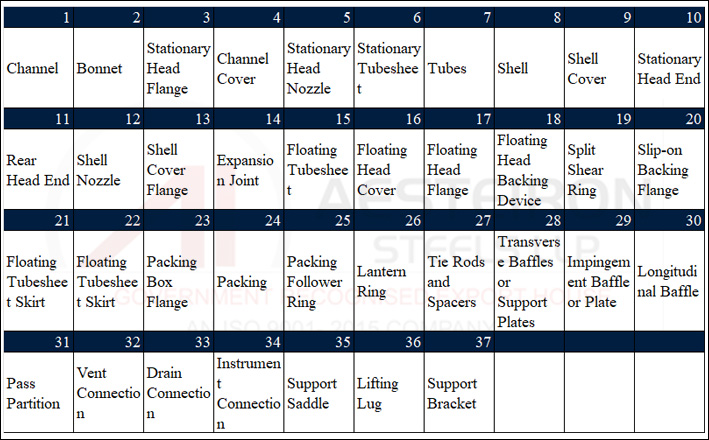

Examine the components and working principle of U tube shell and tube heat exchanger

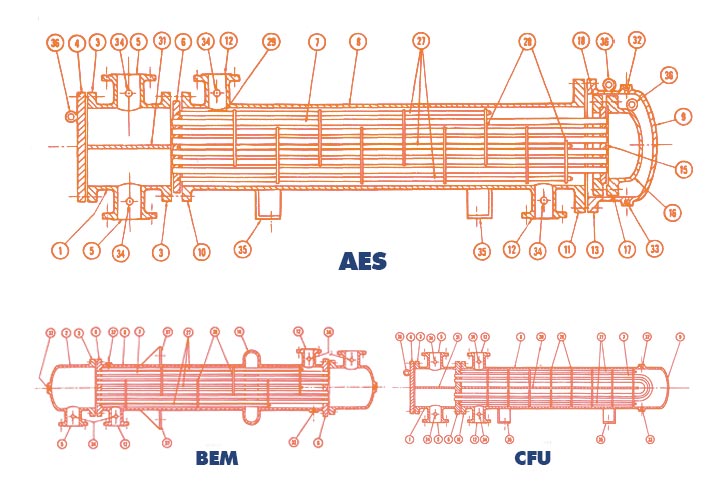

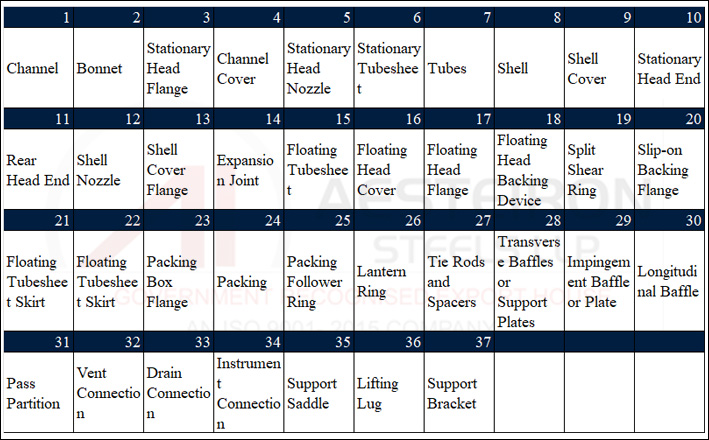

The working principle of U tube shell and tube heat exchanger involves using a shell and tube arrangement to achieve heat transfer. It consists of a shell and multiple tubes. The accompanying image will provide further details on its composition and structure.

Diagram of U Tube Type Heat Exchanger

Comparison: U Tube vs Straight Tube Heat Exchanger

| Feature |

U-Tube |

Straight |

| Construction |

Compact and robust |

Simpler |

| Design |

Fixed at both ends |

Bundled in a shell |

| Cost |

High |

Low |

| Thermal Expansion |

More |

Less |

| Heat Transfer Area |

Good |

Better |

| Maintenance |

More challenging |

Easier to maintain |

| Space Requirements |

Compact |

Bulkier |

| Lifespan |

Longer |

Varies with design |

Comparison: Floating Head vs U Tube Heat Exchanger

| Feature |

Floating Head Heat Exchanger |

U-Tube Heat Exchanger |

| Design |

One end is fixed, the other end is float or movable |

Fixed at both ends |

| Maintenance |

Easier |

More challenging |

| Heat Transfer Area |

Larger |

Efficient |

| Space Requirements |

Bulkier |

Compact |

| Cost |

High |

Low |

| Lifespan |

Long |

Robust |

U type heat exchanger is widely used in petroleum and chemical machinery

As we know, heat exchangers facilitate smooth heat transfer between two separate channels, either in direct contact or separated by a large barrier to prevent mixing.

In the realm of petroleum and chemical machinery, U-type heat exchangers are favored due to their compact structure, high heat output, and ability to withstand high pressure. These features reduce the risk of heat-induced stress and failure, enhancing resilience under adverse conditions.

Applications of U Tube Condenser

- Pressure vessels

- High-pressure equipment

- Cryogenic pressure vessels

- Boilers

- Air cooler tubes

- Tube sheets of heat exchangers

- Refineries

- Air preheater

- Fertilizer plants

- Chemical factories

- HVAC systems

Benefits of U Tube Shell and Tube Heat Exchanger

- High Efficiency

- Enhanced Heat Transfer

- Compact Design

- Reduced Maintenance

- Versatility

- Excellent Durability

- Cost Effective

- Easy Installation

Explore the advantages and disadvantages of U-Tube heat exchangers

Advantages of U Tube Exchanger

- Recyclable

- Energy-saving

- Wide range of designs

- Cost-effective

- Extensive material options

- Space-saving designs

- Good thermal compensation

- Easy maintenance

- Handles diverse flow rates, fluids, and temperatures

Disadvantages of U-Tube Heat Exchanger

- Limited suitability for large temperature ranges

- Warping due to temperature differences

- Requires more space

- Needs regular cleaning

- Complex structure

- Prone to internal leakage

Calculation of U Tube Heat Exchanger

Crossover Temperature of U Tube Shell and Tube

| Temperature |

Water |

Oil |

| Outlet |

51.5 |

50 |

| Inlet |

30 |

80 |

| Flow Rate |

15 L/min |

25 L/min |

This detailed overview highlights the versatility and functionality of U-tube heat exchangers, making them indispensable in numerous industrial applications.

Netball

We can provide rubber netball and machine stitched netball ball.We have been working with the Australian market for a long time, so we have a great advantage in the production of netball, with a full range of molds, sufficient capacity, and the ability to provide customization and design services.

More than 40 years' experiences in this field and SEDEX, ISO, BSCI, COSTCO,YUM etc. certificated qualification and extreme standard let us keep very competitive in the current market.

|

Size

|

Weight(g)

|

Diameter(inch)

|

Packing(pcs/ctn)

|

Carton Size(cm)

|

G.W./N.W.(kg)

|

|

Size 5 netball

|

400-430

|

8.65-8.9

|

50

|

53*31*40

|

22/20

|

|

Size 4 netball

|

350-380

|

8-8.28

|

50

|

53*29*39

|

21/19

|

Netball,Net Ball,Netball Sport,Netball Ball,Junior Netball

Jiangyin Mingde Sports Goods Co., Ltd. , https://www.mdsportsball.com