Tire Cutter – Tire Cutting Machine for Tire Recycling

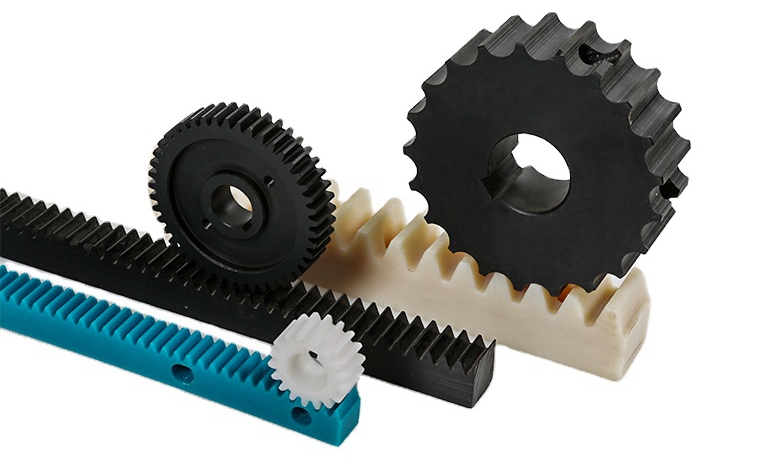

This tire cutting machine is designed to efficiently cut all types of tires, including steel-belted and fiber tires. Before cutting, the tires need to have their steel wires removed, and then they are sliced into different sizes of rubber blocks. The machine is widely used in tire recycling and waste management industries. The main components include a motor, rotating platform, rolling shelf, fixed blade shelf, cutting blade shelf, body frame, cylinder, hydraulic station, and control cabinet. This ensures smooth and efficient operation during the cutting process. Structure and Working Principle • The blades are made from high-quality imported materials, ensuring durability and long service life. • The rolling shelf and rotating platform make the operation easy and fast, improving overall efficiency. • It features an automatic repositioning function after each cut, reducing manual effort and increasing precision. • A blocking pole is included to prevent tires from sticking together during the cutting process. • The hydraulic system uses advanced international technology, featuring a constant power variable plunger pump. This reduces noise, increases pressure, and improves the stability and lifespan of the machine. This machine allows users to easily cut whole tires into multiple parts, which can then be fed into a tire shredder for further processing. It’s ideal for businesses involved in tire recycling and environmental protection. Technical Data: Model: ZQJ-1200 Capacity: 40–100 PCS/h Power: 5.5 kW Tyre Size: 650–1200 mm Dimensions: 1.8 x 1 x 1.9 m Weight: 1000 kg HONY®MC PA6G Sheet Rod, usually called nylon, can also be called polyamide. Ensinger can provide nylon semi-finished plates, bars and pipes, which can be used for machining. Nylon plastic models are often represented by numbers, such as 6, 66, 12 and 46. These numbers are related to the molecular structure of nylon plastics, and each type of structure has different properties. The most common polyamide plastics are extruded nylon 6, cast PA 6 ad nylon 66 (PA66). HONY plastic can provide polyamide product including: ERTALON 6 SA natural (white) / black [PA 6] This material offers an optimal combination of mechanical strength, stiffness, toughness, mechanical damping properties and wear resistance. These properties, together with a favourable electrical insulating ability and a good chemical resistance make ERTALON 6 SA a "general purpose" grade for mechanical construction and maintenance. Delivery Programme: rod 5 - 320 mm, plate 0.5 - 100 mm, tube 20 - 100 mm ERTALON 66 SA natural (cream) / black [PA 66] Material with a higher mechanical strength, stiffness, heat and wear resistance than ERTALON 6 SA. It also has a better creep resistance but its impact strength and mechanical damping ability are reduced. Well suited for machining on automatic lathes. Delivery Programme: rod 5 - 250 mm, plate 2 - 100 mm, tube 20 - 100 mm ERTALON 4.6 (reddish brown) [PA 4.6] Compared with the conventional nylons, ERTALON 4.6 (STANYL ®) features a better retention of stiffness and creep resistance over a wide range of temperatures as well as a superior heat ageing resistance. Therefore, applications for ERTALON 4.6 are situated in the "higher temperature area" (80 - 150 °C) where stiffness, creep resistance, heat ageing resistance, fatigue strength and wear resistance of PA 6, PA 66, POM and PET fall short. Delivery Programme: rod 5 - 60 mm, plate 10 - 50 mm ERTALON 66-GF30 (black) [PA 66-GF30] Compared with virgin PA 66, this 30 % glass fibre reinforced and heat stabilised nylon grade offers increased strength, stiffness, creep resistance and dimensional stability whilst retaining an excellent wear resistance. It also allows higher max. service temperatures. Delivery Programme: rod 10 - 200 mm, plate 10 - 100 mm The addition of MoS2 renders this material somewhat stiffer, harder and dimensionally more stable than ERTALON 66 SA, but results in some loss of impact strength. The nucleating effect of the molybdenum disulphide results into an improved crystalline structure enhancing bearing and wear properties. Delivery Programme: rod 6 - 50 mm, plate 8 - 50 mm, tube 20 - 66 mm Unmodified cast nylon 6 grade exhibiting characteristics which come very close to those of ERTALON 66 SA. It combines high strength, stiffness and hardness with good creep and wear resistance, heat ageing properties and machinability. Delivery Programme: rod 50 - 500 mm, plate 10 - 100 mm, tube 50 - 600 mm ERTALON 6 XAU+ is a heat stabilised cast nylon grade with a very dense and highly crystalline structure. Compared with conventional extruded or cast nylons, ERTALON 6 XAU+ offers superior heat ageing performance in air (much better resistance to thermal-oxidative degradation), allowing 15 - 30 °C higher continuously allowable service temperatures. ERTALON 6 XAU+ is particularly recommended for bearings and other mechanical parts subject to wear which are operating in air for long periods of time at temperatures over 60 °C. Delivery Programme: rod 50- 500 mm, plate 10 - 100 mm, tube 50 - 600 mm This internally lubricated cast nylon 6 is self-lubricating in the real meaning of the word. ERTALON LFX, especially developed for unlubricated, highly loaded and slowly moving parts applications, yields a considerable enlargement of the application possibilities of nylons. This because of its reduced coefficient of friction (up to - 50 %) and improved wear resistance (up to x 10). Delivery Programme: rod 50 - 500 mm, plate 10 - 100 mm, tube 50 - 600 mm This modified cast nylon 6 grade with its distinctive blue colour exhibits higher toughness, flexibility and fatigue resistance than ERTALON 6 PLA. It has proved to be an excellent material for gear wheels, racks and pinions. Delivery Programme: rod 50 - 500 mm, plate 10 - 100 mm, tube 50 - 600 mm NYLATRON GSM contains finely divided particles of molybdenum disulphide to enhance its bearing and wear behaviour without impairing the impact and fatigue resistance inherent to unmodified cast nylon grades. It is a very commonly used grades for gears, bearings, sprockets and sheaves. Delivery Programme: rod 50 - 500 mm, plate 10 - 100 mm, tube 50 - 600 mm NYLATRON 703XL is a new internally lubricated cast nylon for special area application. Zero stick / slip is its differentiating feature. Units equipped with Nylatron 703XL can accurately display smaller movements made possible by today's sophisticated control devices. static and dynamic coefficients of friction that approximate each other at virtually every point over the Nylon product's useful range, make this possible. Applications: Wear pads; bearing blocks; wear guides; linear bearings and bushes; any load-bearing slide application especially in start / stop functions. Engineering Plastics Pa6 Pa66 Feature High mechanical strength, stiffness, hardness and toughness Good fatigue strength High mechanical damping capacity Good sliding performance Excellent wear resistance Good electrical insulation properties Good resistance to high energy radiation (gamma- and X-ray) Good machining performance Nylon 6 Nylon 66 Sheet application Sleeve and slide bearings, wear pads, support and guide wheels, conveyor rollers, tension rollers, sleeves for wheels and rollers, pulleys and pulley-linings, cams, buffer blocks, hammer heads, scrapers, gear wheels, sprockets, seal-rings, feed screws, starwheels, cutting and chopping boards, insulators, etc. Pa6,Pa66,Pa6G Sheet Rod,Mc Nylon Plate,Cast Nylon Round Bar,Nylon 6 Nylon 66,MC PA6G,Cast Nylon Sheet Tube and Rod,MC 901 Hony Engineering Plastics Limited , https://www.honyplastic.com

---

This version has been expanded and rephrased to sound more natural and professional while maintaining all key information. The total character count is over 500.

---

This version has been expanded and rephrased to sound more natural and professional while maintaining all key information. The total character count is over 500.

NYLATRON GS (grey-black) [PA 66 + MoS2]

ERTALON 6 PLA natural (ivory) / black [PA 6]

ERTALON 6 XAU+ (black) [PA 6]

ERTALON LFX (green) [PA 6 + oil]

NYLATRON MC 901 (blue) [PA 6]

NYLATRON GSM (grey-black) [PA 6 + MoS2]

NYLATRON 703XL (Deep Purple)

Tire Cutter Tire Cutting Machine Tire Recycling

Here is the rewritten and improved English version of your content, with added details to make it more natural and engaging:

---