Mold Parts,Custom Injection Mold, Injection Mold Manufacturing, Precision Mold Components Dongguan Hao Chen Precision Industry Co., Ltd. , https://www.howmolds.comWhat is Insert Molding?

Insert molding is a process in which pre-formed components are placed into a mold before plastic is injected, resulting in a single, bonded part. For instance, threaded inserts are often molded into fasteners, while metal contact pins are used as inserts in connectors. This method not only reduces individual part costs but also eliminates the need for assembly, leading to significant cost savings.

Insert molding allows for the combination of the advantages of both materials—plastic’s lightweight and flexibility, and metal’s strength and rigidity. This results in a more durable and functional product. However, if the components are custom-made rather than off-the-shelf, this can add extra time and cost to the production process.

When to Use Insert Molding

Consider using insert molding when your design requires:

- A metal component

- Threaded inserts

- A sub-assembly (such as embedded wires, electronic parts, or circuit boards)

How to Use Insert Molding

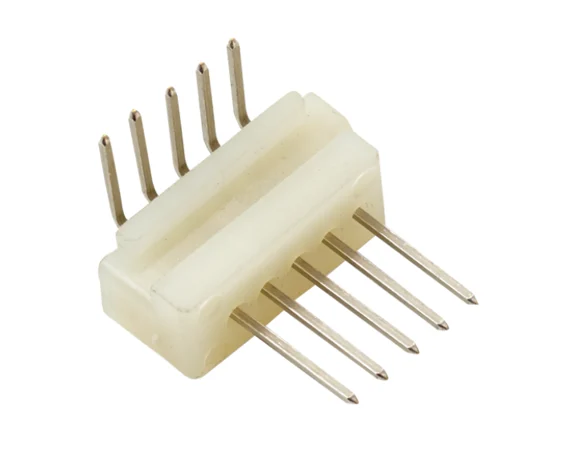

Insert molding offers a creative approach to design. Components like Right Angle Pin Headers can be mass-produced as sub-assemblies, making it easier to place them into the molding machine. This streamlines the process, reducing both time and cost.

No matter how you plan to use insert molding, having all the necessary files ready for engineers or designers is essential. The final design should include insert CAD to visualize the space the inserts occupy. This helps assess how the inserts might affect the structural integrity of the product. Any DFM (Design for Manufacturing) considerations must also be documented to ensure quality control before production begins.

What is Overmolding?

Overmolding is a variation of insert molding where a second layer of plastic is molded over an existing part. The first component is created in an injection mold and then placed into a second mold to form the final product. This technique is commonly used in handles, where a softer plastic is molded over a rigid core to improve comfort.

By combining multiple materials into one component, overmolding reduces assembly costs and eliminates the need for adhesives. It also allows for enhanced features like different textures, colors, or properties. This method is especially useful for embedding soft seals or creating complex assemblies.

Another example is pin assemblies, where multiple pins can be molded at once instead of being placed individually. This ensures precision and saves time during the manufacturing process.

However, if the temperature is not properly controlled, delamination may occur. Since overmolding typically requires two molds or a more complex two-shot mold, it tends to be more expensive than producing a single part. But when compared to assembling two separate parts, overmolding is often more cost-effective.

When to Use Overmolding

Use overmolding when your application needs:

- Different thermal or electrical properties

- Shock absorption or vibration damping

- Multiple colors

- A comfortable, non-slip grip

- Embedded soft seals

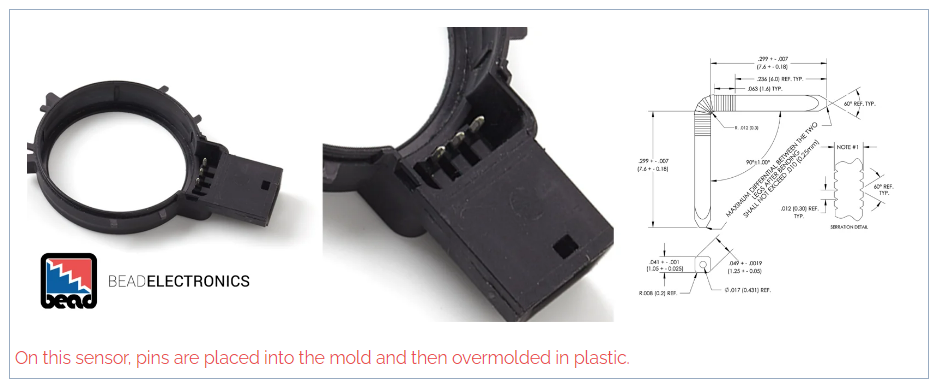

Overmolded parts can also be customized further if needed. Their durability makes them ideal for the automotive industry. For example, contact pins can be overmolded with plastic or rubber and used in connectors for vehicle sensors, control units, or infotainment systems.

Choosing between insert molding and overmolding depends on the specific needs of your project. While insert molding is usually more cost-effective and faster, custom designs may change that dynamic.

Whether you're looking for insert-molded or overmolded connectors, or complete overmolded assemblies, Bead Electronics has extensive experience providing pins for various applications in industries like automotive, telecom, aerospace, industrial, and medical.

Bead's contact pins can be used in power, signal, or electro-mechanical applications as part of an insert-molded or overmolded connector.

Contact us today to speak with a specialist!

The Difference Between Insert Molding and Overmolding;Â What You Need to Know

Molds have transformed the manufacturing landscape, enabling suppliers to produce identical parts at high speed. Injection molding, a process where molten plastic is injected into a mold to create components, is widely used across industries such as automotive, aerospace, industrial, and medical. This technique can be further divided into two main types: insert molding and overmolding.